Structures Taking Full Advantage of Composite Material Properties

Carbon fiber tufting on glass preform (top view)

The composite material sector is rapidly expanding. The aeronautics industry has long history in this field, but a growing number of other industries have now also understood the advantages that composite materials can offer when compared to metals. Composites are extremely resistant, stiff and light, while also offering more flexibility in terms of the shapes into which they can be manufactured.

Several major players in a range of sectors such as wind energy, land transportation and sports make use of this material for structural and non-structural parts. Although production of composites has more than doubled over the past 20 years, Simon Joncas, researcher and professor in the Systems Engineering Department, believes we are at a crossroads: as we enter the Industry 4.0 era, we need to find a way to move from labour-intensive manufacturing processes to large-scale automated manufacturing of composite parts. We need to go beyond producing parts in small quantities to be able to produce greater volumes.

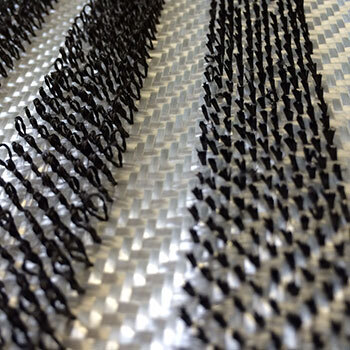

Carbon fiber tufting on glass preform (bottom view)

TTR composites, extraordinary progress

The development of new materials used in composite structures, including composites made with 3D textiles or through-thickness reinforced (TTR) 2D textiles, has made significant progress. TTR composites offer new opportunities for structural design and manufacturing, which Dr. Joncas and his students are now closely studying.

One of them is the ability to create 3D textile preforms or assemble 2D textiles using automated sewing techniques to reduce production costs and increase the quality of finished parts. In terms of design, using TTR composites increases resistance to delamination and can help optimize the performance of parts subjected to complex loads, all of which is very encouraging.

From wind energy… to figure skating

Simon Joncas, Professor in the Systems Engineering Department at ÉTS

The wide range of projects on which Professor Joncas collaborates points to composites’ many uses. After earning a Ph.D. in the field of wind energy at Delft University of Technology in the Netherlands, one of Europe’s most important composite materials research centres, he and his students have been contributing to the development of this industry for the past 10 years. Over this time, he has broadened the scope of his research and has led several projects in the aeronautic, aerospace, sports and energy sectors. Apart from pursuing his research on TTR composites, he also on a polymer-based high-voltage capacitor (180 kV), and is currently developing a heel for figure skates made of composite materials that would better absorb shocks.