Recovering Forest Biomass

Purchased on Istockphoto.com. Copyright.

An Untapped Resource

Logging generates significant amounts of wood residue left behind at the harvesting sites. These logging residues combined with other sources of forest biomass—small-diameter trees or trees with natural defects, low-value hardwoods, and dry or insect-infested wood—make up the forest biomass. Although unusable for lumber or paper production, forest biomass remains attractive for wood pellet processing.

Wood pellets are a renewable energy source that can help reduce our dependence on fossil fuels. It is also possible to transport pellets over long distances, as their energy density is very high (compared to wood chips for example).

In this research project, conducted at the FORAC Research Consortium, we studied the possibility of integrating a new business unit into the value chain of existing forest products—a forest biomass-based pellet plant. This research focuses on Côte-Nord region (province of Quebec). Challenges encountered in this region include the hydrography and topography of the land and the distance between harvesting sites and processing plants, making access to resources very difficult/costly, and the lack of railways, which restricts market access.

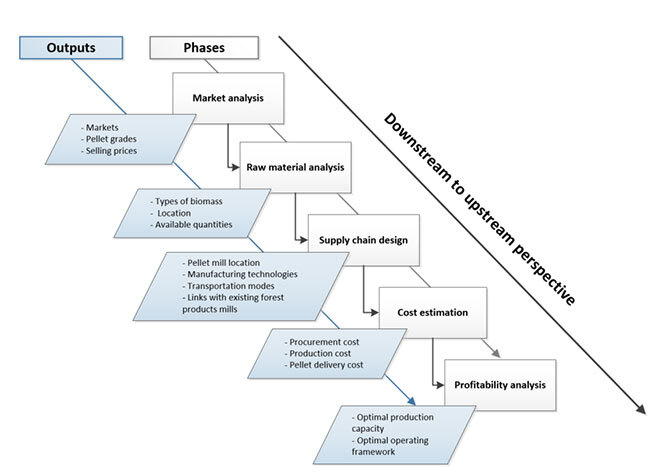

The following figure summarizes the different stages of our analysis.

Figure 1: Analysis of the wood pellet value chain

Market and Supply

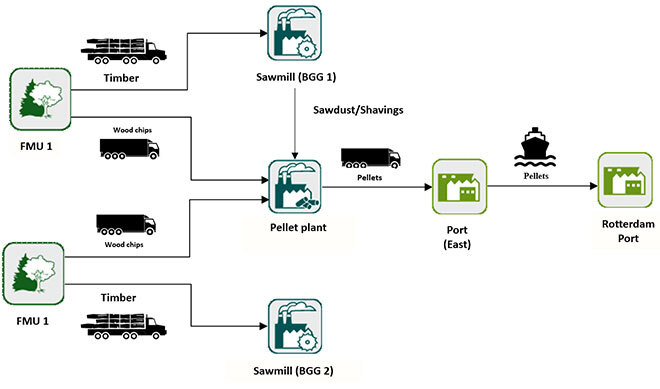

The European market is the most attractive for wood pellets from Eastern Canada due to high demand and relative proximity compared to the competing Western Canada region. In terms of raw materials, the supply analysis showed that only two of the six management units in Côte-Nord region had biomass deposits large enough to justify harvesting costs. The possibility of adding residues of a sawmill located near Baie-Comeau (BGG 1) to forest-harvested biomass was also considered. A theoretical biomass that could feed the future pellet plant was therefore estimated at 185 thousand tonnes per year.

Figure 2: Geography of the target area

Logistics Network Configuration

The only port located close enough to the selected management units and the sawmill is in Baie-Comeau (East Port). Land adjacent to the sawmill could accommodate the future pellet plant. The following figure summarizes the logistics network configuration.

Figure 3: Logistics network configuration

Profitability Analysis

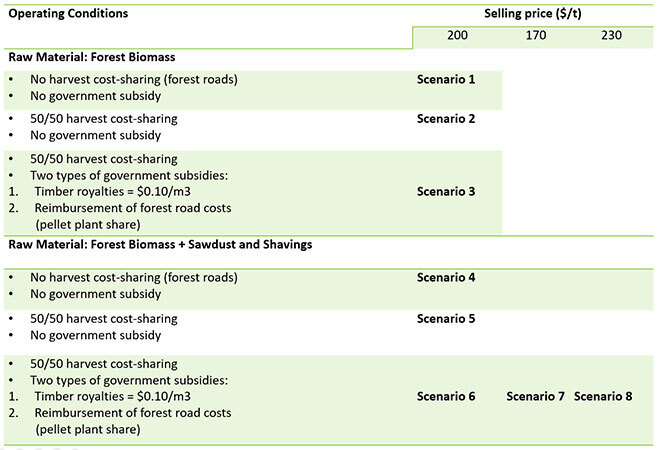

As shown in the following table, several scenarios were considered, depending on the source of the biomass, the selling price of the pellets, and the presence or absence of government incentives and harvest cost-sharing mechanisms. Two production capacities were considered: 50,000 and 100,000 tonnes/year.

Figure 4: Scenarios selected for the business case

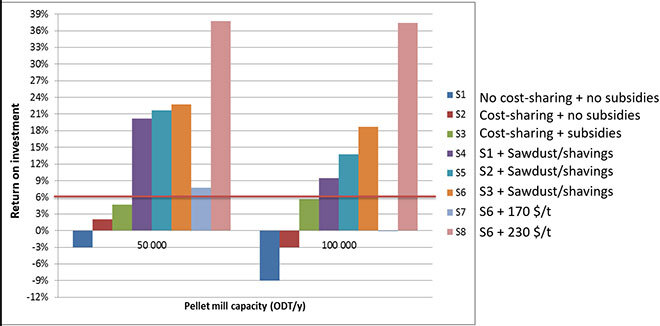

The following figure shows the return on investment for the selected scenarios.

Figure 5: Return on investment of the selected scenarios

Conclusions

A pellet plant fuelled only with forest biomass would require a capacity of over 100,000 tonnes/year to be profitable. On the other hand, a 50,000 tonne/year plant provides a better return on investment when sawdust/shavings are added to the forest biomass. Of course, a larger plant may be feasible if government subsidies were available, thereby maximizing job creation and economic benefits.

Additional Information

For more information on this research project, please refer to the following publications:

Boukherroub, T., Lebel L., Lemieux S. (2017). An integrated wood pellet supply chain development: selecting among feedstock sources and a range of operating scales. Applied Energy. 198: 385-400.

Boukherroub, T., Lebel L., Lemieux S. (2015). Vers la valorisation de la biomasse forestière dans l’Est canadien : une étude de cas au Québec. 11e Congrès International de Génie Industriel (CIGI’15), 26-28 octobre, Québec City.