Energy Efficiency for Poultry Shelters in Québec

Purchased on Istock.com. Copyright.

A predictive digital simulation model of the energy consumption of a poultry shelter was formulated, developed and validated to improve the energy efficiency of Québec’s poultry production. The digital code or program incorporating this model should allow for the implementation of measures and technologies aimed at reducing farmers’ dependence on fossil fuels, heating costs and, consequently, their GHG emissions. Keywords: energy efficiency, poultry shelter, thermal balance, moisture balance, heat recovery, digital modelling

Aviculture: An Energy-Intensive Industry

Poultry farming is an important market for Québec and energy efficiency has become a major issue, both for ecological and economic reasons. Poultry shelters are very energy-intensive productions, generating relatively low profit margins for producers, especially in the context of the Canada-United States-Mexico Free Trade Agreement (CUSMA), which further opens up the Canadian poultry sector to American competition. Reducing energy bills and dependence on fossil fuels is giving Québec producers, who make up 30% of the Canadian market, more and more of an edge.

One constraint on this production is that poultry shelters are enclosures that require a lot of ventilation, which is usually done by installing exhaust fans on the building walls. Air intake comes through hatches located on the walls opposite those equipped with the fans. To compensate for heat loss due to ventilation requirements, heat exchangers like the ESA1000 can be used. The heat exchanger is a double pipe countercurrent recovery ventilator that recovers heat from stale air (loaded with dust, humidity, CO2 and ammonia) expelling it from the building and preheating incoming fresh air. So, for instance in winter, instead of having air entering at -15 °C, the intake is brought up to around 0 °C. The temperature gain reduces the amount of energy required to heat indoor air to the set point, which can vary from 23 °C to 32 °C depending on the age of the chickens. The breeder therefore saves on propane or natural gas consumption and at the same time reduces greenhouse gas (GHG) emissions.

A Three-Tiered Research Project

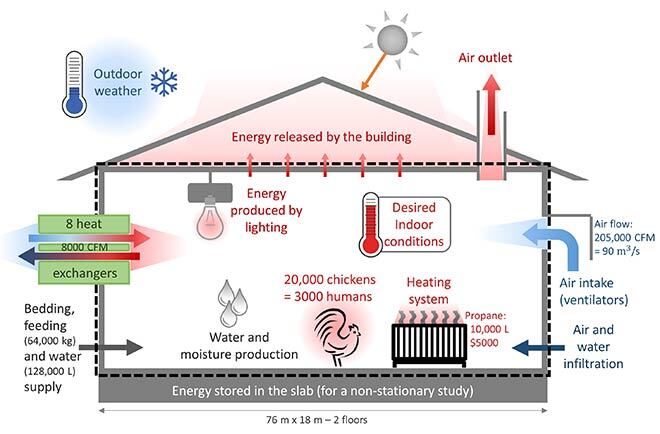

The first objective of this project was to develop a detailed heat balance model for a poultry breeding building in terms of sensible and latent energy (water balance). Specifically, all sources of thermal generation and heat transfer to and from the building (walls, cracks, openings) must be addressed. In addition, two types of thermal flows must be quantified: those that cause temperature changes (sensible heat) and those that involve a phase change of water (latent heat). Also, heat and water released by the chickens must be adequately modelled.

Figure 1 Diagram of heat and water generation, gain, and loss in a poultry shelter

The second objective was to develop a digital code simulating a poultry shelter operation and to validate this code using reference data provided by a Québec breeder. The third objective was to use the code to simulate the reference building’s typical annual production, with and without heat exchangers, and with two scenarios of heat exchanger control (exchanger model: ESA1000).

Two documents published by the American Society of Agricultural and Biological Engineers (ASABE) were used to develop a stationary mathematical model per hour [1–2]. One overriding challenge was the characterization of sensitive and latent heat exchanges produced by livestock. This type of energy is significant at the end of the production process, when the animals have reached maximum growth. However, literature on the subject fails to rule on a highly correlated model or models. The equations developed by Xin & al. in 2001 and validated by several other studies seem to provide the best approach to date [3] and made it the approach favoured by researchers from the Industrial Research Group in Technologies of Energy and Energy Efficiency (t3e).

Model Predictions

The digital model entered in Matlab provided results that agreed with those collected on site and the predictive simulation error rate is estimated at around 9% for total heating consumption.

Following are the main results:

(1) Sensible heat released by birds ranges from 60% (in winter) to 85% (in summer) of the total heat gain with the remainder coming from heating devices. Mechanical ventilation is responsible for almost all loss, while loss caused by the building envelope represents at most only 3% of total loss;

(2) After calibrating the model for the building under study, simulations with BHEC (Broiler House Energy Computation) predicted the annual heating consumption with a 9% error;

(3) The ESA1000 exchangers must be controlled by a central regulation system—not the case with the partner breeder—a configuration that would allow savings of up to 60% on annual heating costs.

Conclusion

The study revealed a sub-optimal use of heat exchangers by the partner breeder—not controlled by a central system—and modifications were proposed to improve average annual efficiency and maximize heat savings.

This model is still neither complete nor perfect. It requires prior calibration that could jeopardize the relevance of a predictive model. Improvements should be made possible through future research projects. In any case, the study has demonstrated the relevance of such a model to correctly and quickly simulate a poultry production system. Moreover, this is the first time that the performance of ESA1000 heat exchangers has been demonstrated and quantified digitally, with accuracy and with such a large amount of data.

This study is part of a broader thought process on reducing the energy costs of Québec poultry shelters conducted by the ÉTS t3e Industrial Research Group. It was the subject of a conference paper for the Colloque International Franco-Québécois de l’énergie, held from June 16 to 19, 2019.